In a world flooded with plastic, you must have come across a recycle loop symbol. The three arrows looping back on themselves in a clockwise direction are among the most recognizable images in the world. However, not many consumers know all the specifics that this familiar character is presenting.

Also known as the Möbius strip in mathematics, this symbol indicates that the plastic product can be recycled, but not necessarily that it has been itself produced from recycled materials. Sometimes you can notice a percentage figure within or next to the recycling loop, indicating how much the product comes from recycled materials.

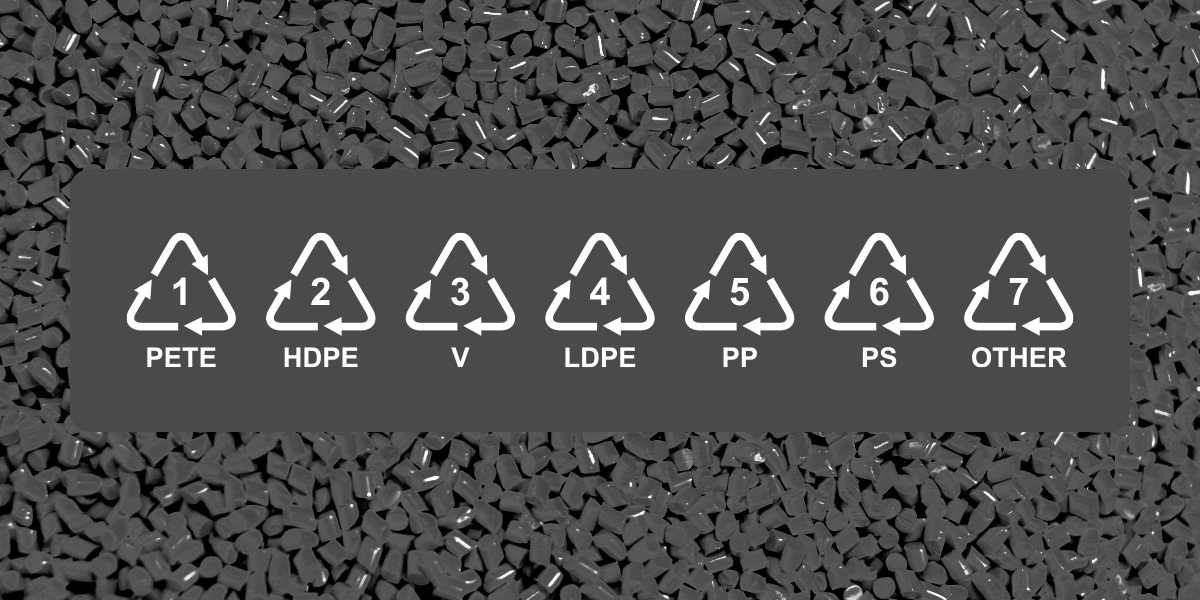

Nowadays, all plastic products should come with an engraved SPI number from one to seven, providing recyclers with information on how to efficiently identify plastic items that could be recycled and what is the best way to do so. The system was developed back in 1988 by The Society of the Plastics Industry (SPI) and stands as one of the global canons in recycling.

Let’s have a look at what each of the numbers in the recycle loop stands for:

Number 1: Polyethylene terephthalate (PET or PETE)

Number 1: Polyethylene terephthalate (PET or PETE)

Polyethylene terephthalate is a type of plastic most often used for bottles and other kinds of food and drinks containers. Its most recognizable feature is transparency. After we used them, plastic bottles can be turned into the polyester. These fibers can then be woven together to make durable carpets and warm winter clothes such as fleeces. Pretty amazing, right?

Number 2: High-density polyethylene (HDPE)

This type of plastic is similar to PET but firmer and not transparent. Manufacturers commonly use number 2 to indicate containers holding chemicals such as shampoo, laundry detergent, or bleach, but it can also be used for storing any sort of food or drink. When recycled, HDPE can be used to make flower pots or plastic crates.

Number 3: Polyvinyl Chloride (PVC)

This type of plastic comes in two forms: stiff and flexible. It can be found in cooking oil bottles, bags for bedding, toys, window frames, table cloths, blister packs, and even plumbing pipes. PVC can later be recycled and used in different industries, often as a flooring material.

Number 4: Low-density polyethylene (LDPE)

A recycle loop containing the number 4 indicates plastic used in flexible packagings, such as frozen food bags, bread bags, and ordinary shopping bags. This low-density plastic can be recycled into a higher density product such are garden furniture and rubbish bins. However, governments worldwide are increasingly trying to reduce LDPE by imposing small fees upon plastic bags. These are small steps, but nonetheless, they bring us closer to achieving a zero-waste lifestyle.

Number 5: Polypropylene (PP)

Number 5: Polypropylene (PP)

Polypropylene can be found in bottle caps, medicine bottles, and tupperware, as well as yogurt, cottage cheese, and hummus containers. It can be recycled into all sorts of items, including ice scrapers and even bike racks, but hey, if you are really serious about making an impact, try using Skaza’s tableware, made from entirely renewable sources. These sugar cane bioplastic products are 100 % recyclable! Did you know that each metric ton of bioplastic produced from sugar cane lowers carbon dioxide emissions by 2 to 2.5 metric tons on a lifecycle basis?

Number 6: Polystyrene (PS)

Polystyrene, more commonly known as foam packaging, is mostly used in - you guessed it - packaging. It is not only the squeakiest of plastics as it indeed makes you shiver; PS is also one of the trickiest to recycle since the process uses a lot of energy. Widespread use for recycled polystyrene is as insulation for walls and roofs.

Number 7: Everything else

Number 7 within the recycle loop refers to all other types of miscellaneous plastics that don’t fit into the categories mentioned above. The most common types represented here are polycarbonate (used in roofing) and polylactide (used in 3D printing). Other well-known products marked with number 7 are also water cooler bottles and baby bottles. Since this category is very broad, there are no straightforward answers about its recyclability, but fortunately, most can be effectively turned into plastic lumber, which has multiple industrial uses.